Change language:

The Notching Process: essential techniques & applications

Sponsored content

The notching process is a basic procedure in sheet metal fabrication. It involves cutting sections or “notches” on the edges of sheet metal. Notching allows the metal to bend, fold, or even attach itself to another part, making it extremely useful in complicated designs. Notching is generally utilized in industries that use highly critical and customized metal parts, such as automotive, aerospace, electronics, and construction.

Notching is one of the favorite processes in modern fabrication because of its accuracy and efficiency. Let’s discuss it in more detail.

What is Notching?

Therefore, what is notching? Basically, it’s a cutting process where parts of the material are removed from the edge of a metal sheet or plate. The sizes and shapes of these notches may differ according to design requirements. Notching is often the first stage in preparing sheet metal for further processes, such as bending, folding, or assembly.

Notching Process

For example, it excellently serves to create the corners in a metal frame; it provides the fit of the pieces into each other so that they merge into one well-shaped component. This ability makes notching an extremely important tool in the production of high-quality metal products, and companies use it to develop accurate components for their clients.

Types of Notching Techniques

There are various types of notching techniques in sheet metal fabrication that produce different designs. Among the most common ones include;

1. V-Notching:

Cuts a V-shaped notch into the metal. It is very popular for creating sharp angles and corners. Its application is found mainly in brackets and frames.

Notching Techniques

2. L-Notching:

Creates an L-shaped cut to fit metal sheets into corners or to join pieces at right angles. It is mainly applied in metal boxes or containers.

3. U-Notching:

Cutting a U-shaped groove, normally for the passage of pipes or other rounded objects. Useful in most HVAC and plumbing applications.

4. Offset Notching:

Allows the flexibility to cut only a portion of the edge at a specific offset distance. This is useful where a perfect fit is anticipated in places where two sheets of metal overlap slightly.

These techniques are applied using tools called sheet metal notchers. Since the type of notching technique chosen depends on the material and its desired shape and application, this technology allows for design versatility.

Material Selection in the Notching Process

Notching Process

The right material for notching is crucial, to be selected. Metals do not respond equally to notching, and every material has features that describe how well it can be cut, shaped, or formed without breaking or deforming. For example:

Steel:

This is one of the common metals used in sheet metal fabrication due to its strength. Additionally, steel can easily be notched without losing its shape and strength is possible for high-demand projects.

Aluminium:

Aluminum is light in weight and resistant to corrosion. This makes aluminum suitable for aerospace and electronic applications. Nevertheless, it is also sensitive to notch cracking as it is notch sensitive and gets damaged easily while being notched.

Stainless Steel:

This metal is highly resistant to corrosion and suitable for both structural and decorative applications. To avoid problems during cutting, it requires quite precise notching tools.

We understand that the proper material selection is key to the success of any sheet metal fabrication job. We build close relationships with clients to tailor the selection of appropriate materials for their project specifications and ensure optimum performance and durability.

Applications of Sheet Metal Notching

Sheet metal notching is a process that is used in almost every industry for custom-made parts made of metal. Here’s a closer look at where it’s applied:

Automotive Industry:

Notching is applied in vehicles in some frames and parts, such as exhaust pipes and engine parts. The parts need to be precisely aligned to assure proper safety and good performance. Accurate notches will be required for an excellent fit, which is important to minimize vibration and wear.

Aerospace Industry:

Components such as aircraft parts undergo tremendous stress, and any notched components must have a fit that does not compromise the structure. Notching is mainly used in this sector to produce parts that can withstand extreme conditions.

Electronics and Appliances:

Notching allows for metal casings that safely house electronic components like circuit boards and wires in appliances. The same is used in microwave ovens, washing machines, and computers.

Construction:

Notching is a construction feature that enables the connection of structural metal frames, supports, and connectors without requiring bulky fasteners. It allows for effective, rigid, and durable construction.

These examples demonstrate how notching sheet metal is integral to the creation of strong, custom, and functional parts in a broad spectrum of industries.

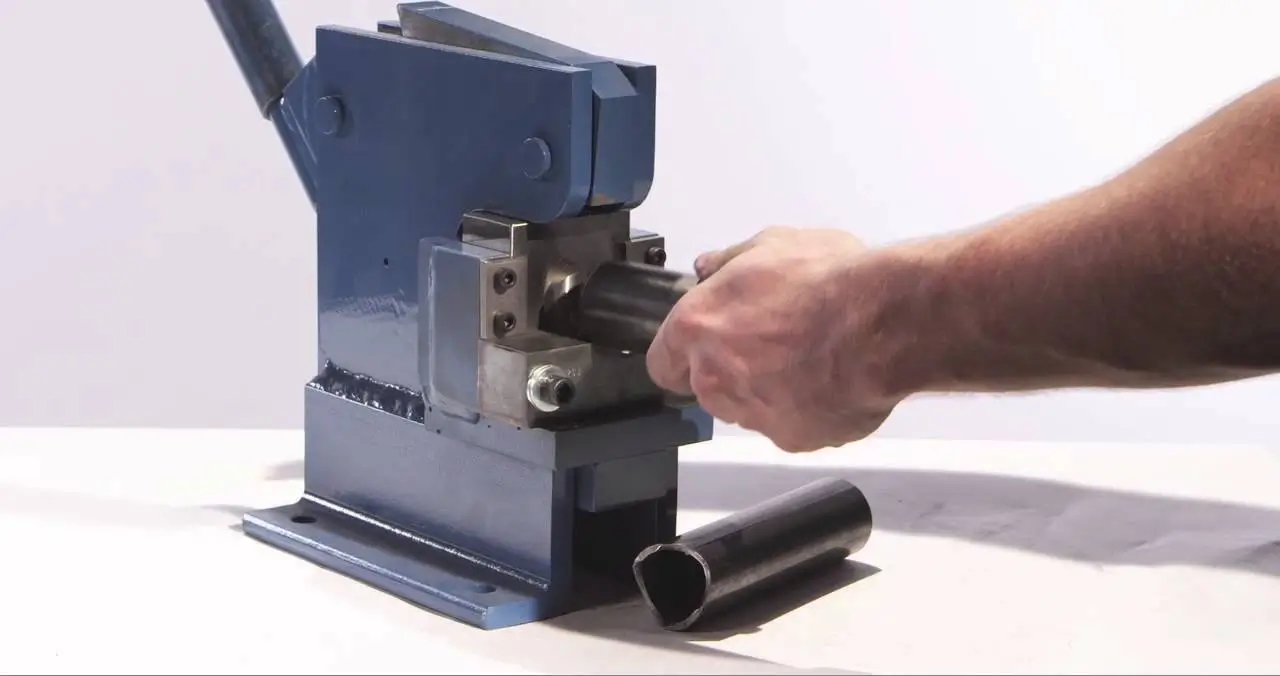

Equipment and Tools for Notching

The notching depends on special machinery to make clean cuts. Today, there are several kinds of sheet metal notchers that have various applications suited for a determined scale of production:

- Manual Notchers: Hand-operated simple, quite affordable, and great for small projects.

- Hydraulic Notchers: Hydraulic Notchers Hydraulic notching machines are cut in deep, fast cuts. These machines are ideal for high volume production of large sheet metal pieces and medium numbers.

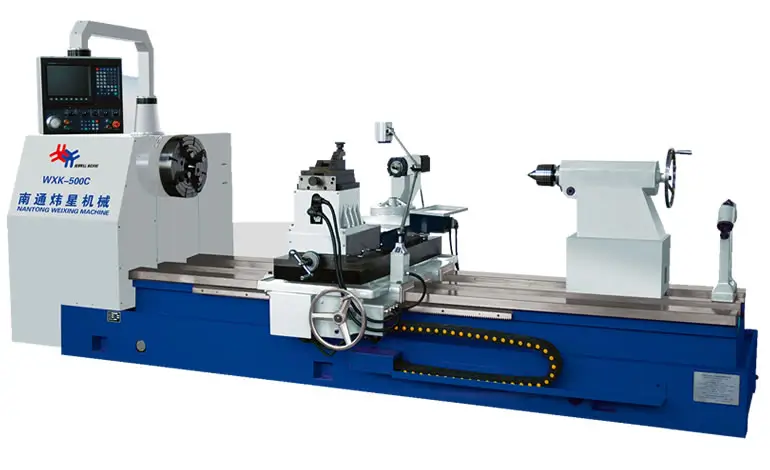

- CNC Notching Machines: These are computerized machines used for heavy-duty and repeated cuts. CNC notchers are used in high-volume production because they are consistent and precise and do not rely on human error.

Thanks to innovation in sheet metal fabrication technology, notching has become faster, more precise, and versatile. Using CNC-powered machines lets ProleanTech handle complex projects and make customized parts with minimal waste.

Benefits of the Notching Process

The notching process offers a number of significant advantages, which make it invaluable in sheet metal fabrication:

Notching Process

More Accurate:

Notching allows easy cutting of the metal pieces with such accuracy that allows them to fit without any further fitting. This is especially important in jobs involving components requiring high tolerability.

Less Material Waste:

Because of notching, materials are cut more efficiently, thereby reducing waste and cost production. It is, hence, both environment-friendly and cost-effective.

Quicker Assembly:

Easy-to-assemble parts notches are convenient in high-volume production environments. The faster a part assembles, the less labor time it will require and the sooner it will be completed.

Quality Control in Notching

Maintaining high standards in the notching process is highly critical for delivering quality work. Every notch should have precision, cleanliness, and no defect that might affect the product. Try to maintain tight quality control and check each item carefully. Use CNC machines and advanced sheet metal notchers, every cut has to be held to the specific specifications that allow for tight tolerances and results that are reliable.

Challenges and Considerations in Notching

Despite the benefits of notching, it is not without its own set of problems, including:

Material deformation:

Deep notches can sometimes cause deformation in material, especially in softer metals.

Stress Concentration:

Notched regions may become stress-concentration regions that lead to fracture.

Notch Sensitivity:

Some materials, such as aluminum, become sensitive to cracking along notched areas due to their “notch sensitivity.” That means the sensitivity of a material to weak at its notch area.

To this end, material knowledge and careful machining are the keys. The notching technique should be properly selected so that it will not lead to problems.

The Future of Notching in Advanced Fabrication

The future of notching is bright, given its advancement with automation and CNC technology. Automated notching allows fast and consistent cuts that are time-effective and accurate. In addition, advancements in 3D printing and laser cutting open more possibilities in sheet metal fabrication.

Consider the changing needs suitably. Enhanced notching processes and new fabrication technologies should be considered that are continually supplying notching solutions by modern requirements as industries continue to seek more customized, quality, and sustainability levels.

Conclusion

The notching process is an important sheet metal fabrication process. It provides customized shapes and precise fits needed in various industries, such as automotive, aerospace, electronics, and construction. With such state-of-the-art notching procedures, firms can produce sturdy parts that are trustworthy, long-lasting, and meet stringent requirements.

Disclaimer: the author(s) of the sponsored article(s) are solely responsible for any opinions expressed or offers made. These opinions do not necessarily reflect the official position of Daily News Hungary, and the editorial staff cannot be held responsible for their veracity.