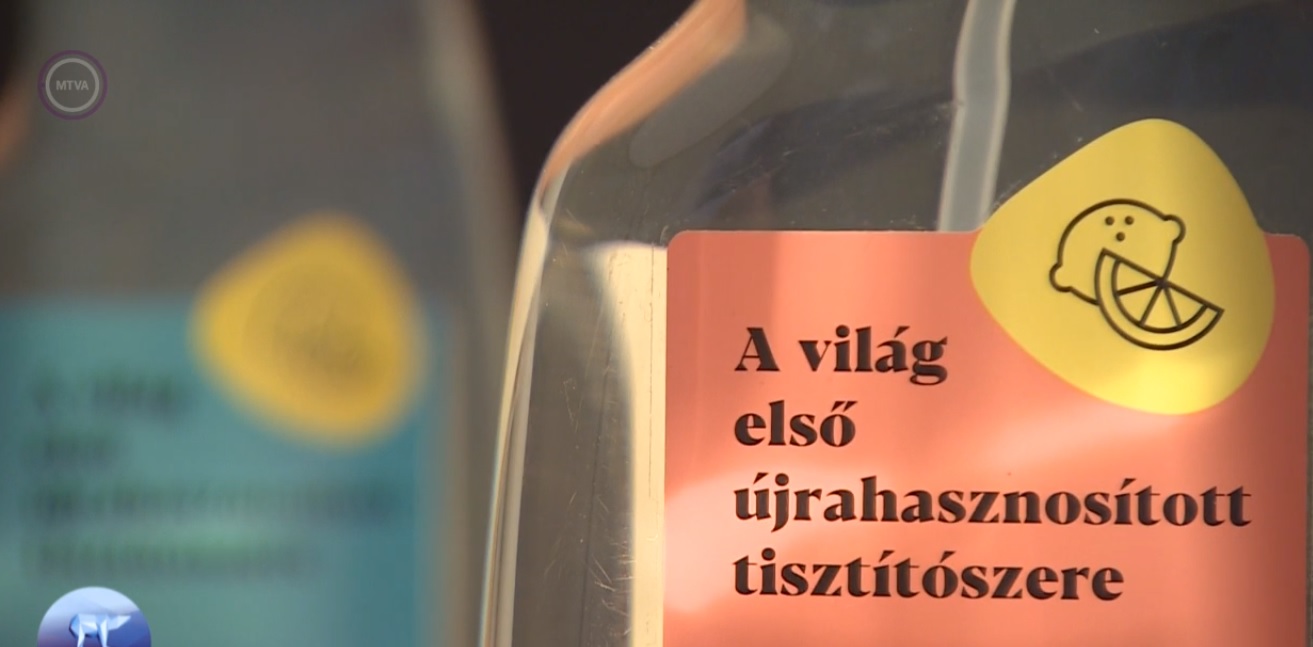

A Hungarian company created the world’s first recycled detergent

A clean home is a happy home – as the saying goes. But what does ‘clean’ mean for the environment? Chemicals? Do you really need all of those? A new invention might solve these questions as a television programme shows a new Hungarian idea – origo.hu reported.

“Cleaning requires two types of detergents, one acidic and one alkaline, or something that has a similar effect” – says Zoltán Vass, Business Development Manager at Renew Technologies. “You need something alkaline to clean grease and something acidic to be able to remove limescale.”

In an average household, you do not need to use strong detergents. Nature provides the solution for almost every cleaning that we need to do in our homes – says the Development Manager.

Vinegar, for example, is a well-known descaler. The Hungarian company Renew Technologies has developed a new acetic acid-based cleaning product. Many could say that this already exists, but this detergent is unique because it is made from recycled, natural materials, with zero water footprint. The company treats the details of their unique recipe as their own business secret. Furthermore, the product is offered in environmentally friendly packaging.

The primary ingredient of the detergent is made from biomass. “To the ordinary eye biomass looks like a waste, but when we look at it, we see it as a source of organic matter and as the source of micro and macro feedstock” – says Beatrix Ari, a lab technician at Renew Technologies. All organic matter like this is called biomass, which contains valuable mineral compounds. Its origin can be industrial, agricultural or even residential.

“We wanted to increase biogas production, – says Zoltán Vass – in other words, to adjust the intensity and efficiency of digestion so that we can get more biogas from a unit of organic waste. Bacteria eat waste, and one bacterial strain produces volatile fatty acids. Another strain then eats these fatty acids and produces methane. We realised that if we could control methalogens so that they would not eat these volatile fatty acids, we could then recover those acids, such as acetic acid, and make a useful product from them.”

About 40 per cent of the biomass can be used to produce acetic acid. The remainder is passed on to their partners for biogas production, so the process is waste-free as well.

It is expected from the finished product only to contain natural ingredients, so they do not colour the liquid, and only organic fragrances are used. The detergent is bottled in a nearby facility, and the selection of the bottle’s composition was also preceded by careful consideration.

Hungarians are famous for their inventions around the world. Last year, a Hungarian startup won Prince Andrew’s prize for entrepreneurs with their device that helps blind people to read. This year, another Hungarian invention helps Africa’s water problem.

“We decided to use 100% recycled plastic. That’s because we use raw materials that are already in the ‘system’” – says Tönki Albert Szabó one of the coworkers of the company.

Even the label of the bottles are made from vegetable fibre. All of these aspects are of paramount importance to developers, who consider the circular economic model to be the guiding principle of the production.

Source video: mediaklikk.hu

Source: origo.hu